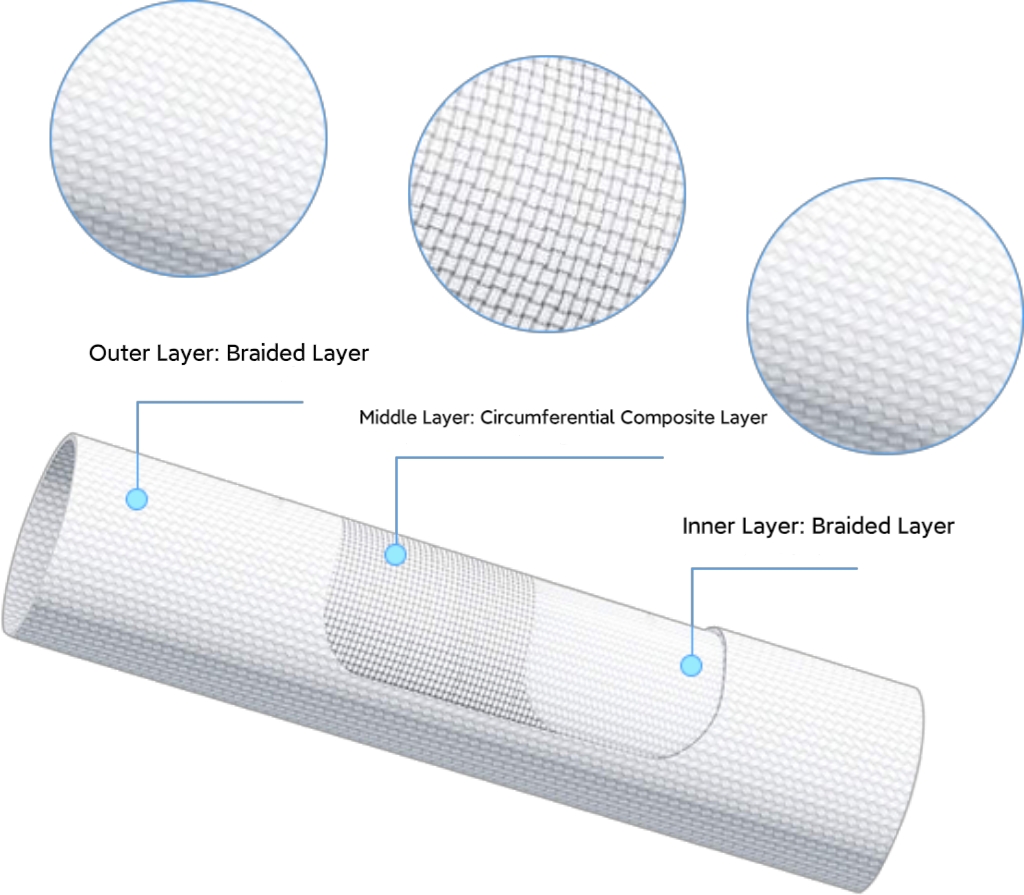

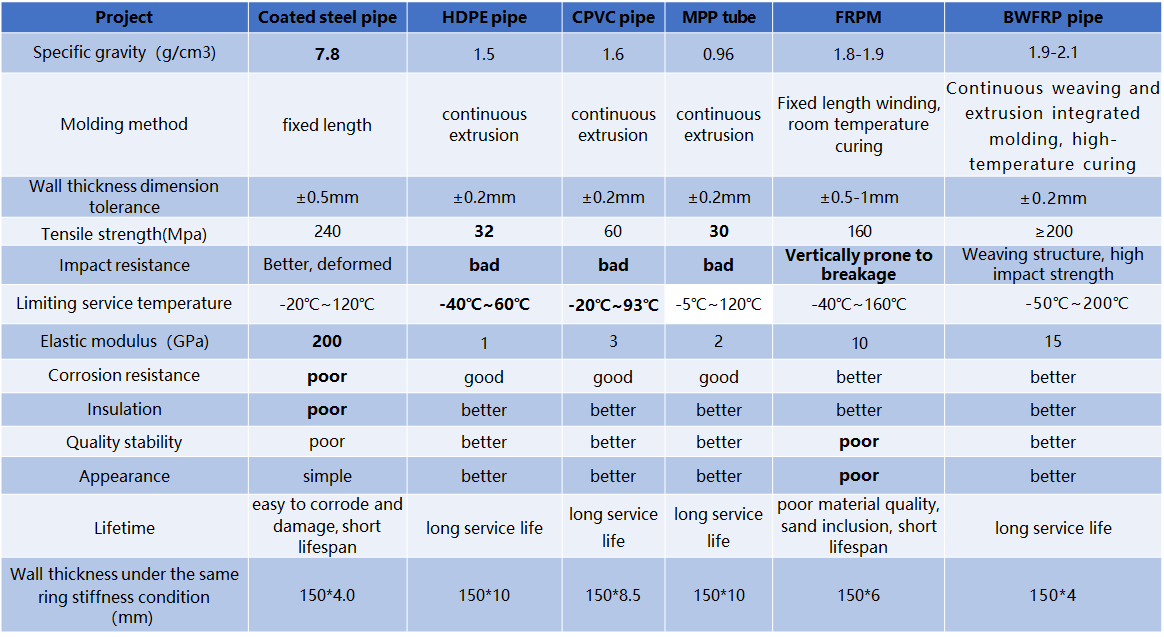

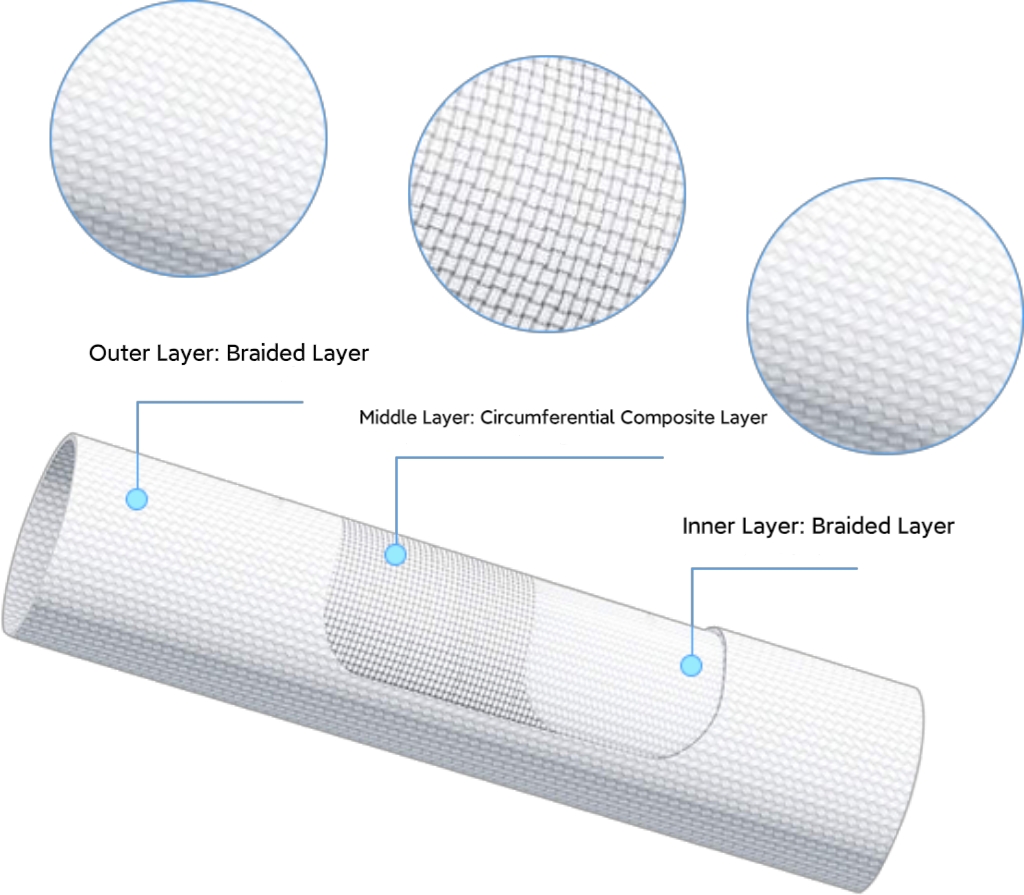

BWFRP (Fiber Braided Pultruded Pipe) consists of an inner braided layer, an intermediate layer, and an outer braided layer. It is continuously composite through fiber braiding, impregnation, and fiber pultrusion, and is suitable for use as protective sleeves for power cables and communication cables. The industry standard was released in 2017. The product consists of an inner woven layer, an intermediate layer, and an outer woven layer, which are formed through a pultrusion process. The ideal composite material product is composed of inner and outer woven layers designed at different weaving angles, as well as longitudinal and circumferential composite intermediate layers. This new type of cable conduit product has advantages that traditional pipe materials cannot match.

BWFRP (Fiber Braided Pultruded Pipe) consists of an inner braided layer, an intermediate layer, and an outer braided layer. It is continuously composite through fiber braiding, impregnation, and fiber pultrusion, and is suitable for use as protective sleeves for power cables and communication cables. The industry standard was released in 2017. The product consists of an inner woven layer, an intermediate layer, and an outer woven layer, which are formed through a pultrusion process. The ideal composite material product is composed of inner and outer woven layers designed at different weaving angles, as well as longitudinal and circumferential composite intermediate layers. This new type of cable conduit product has advantages that traditional pipe materials cannot match.