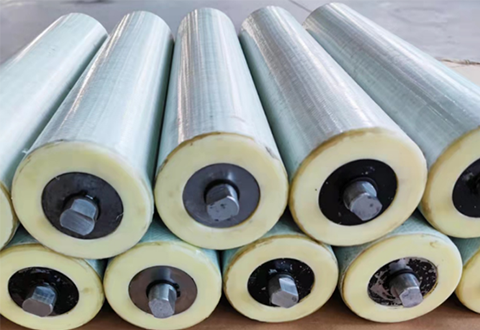

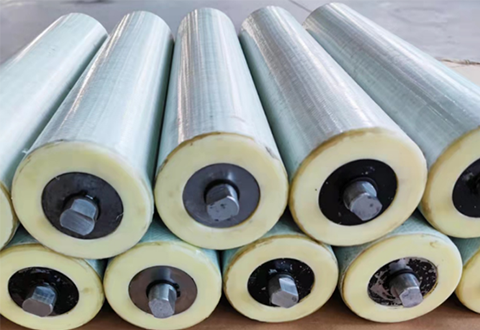

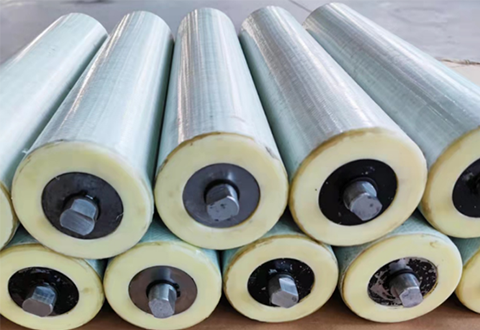

Fiberglass composite roller

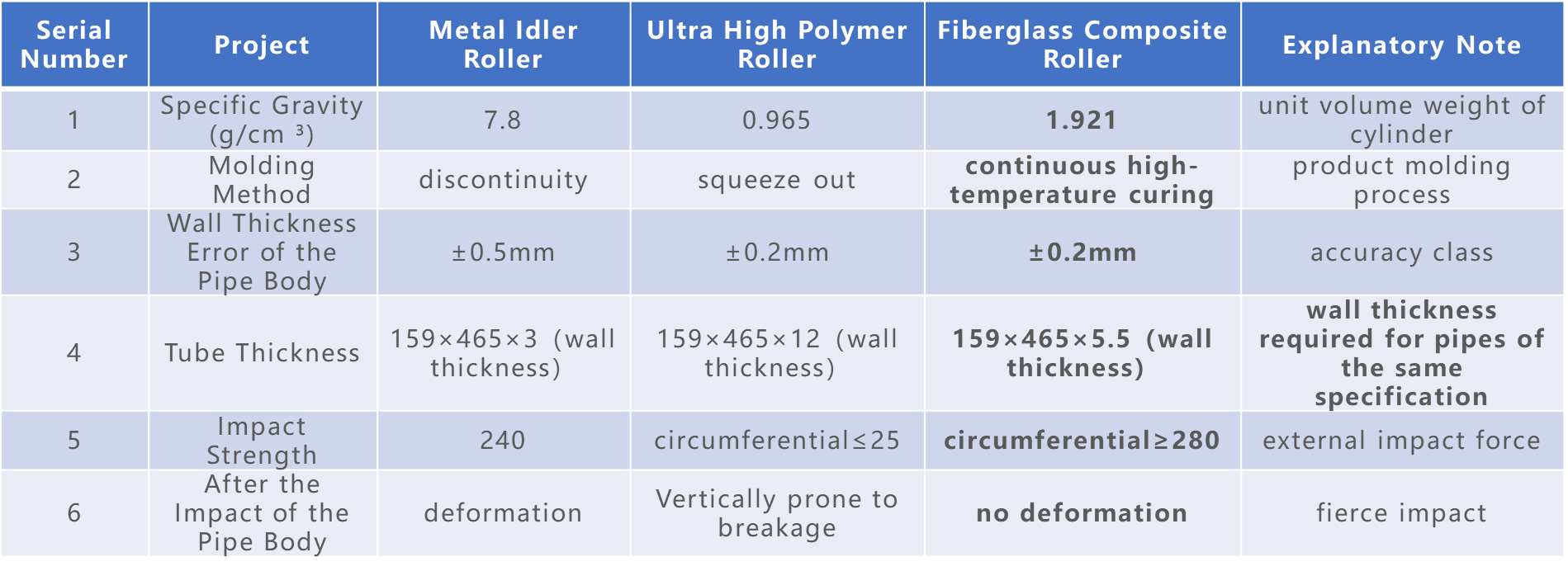

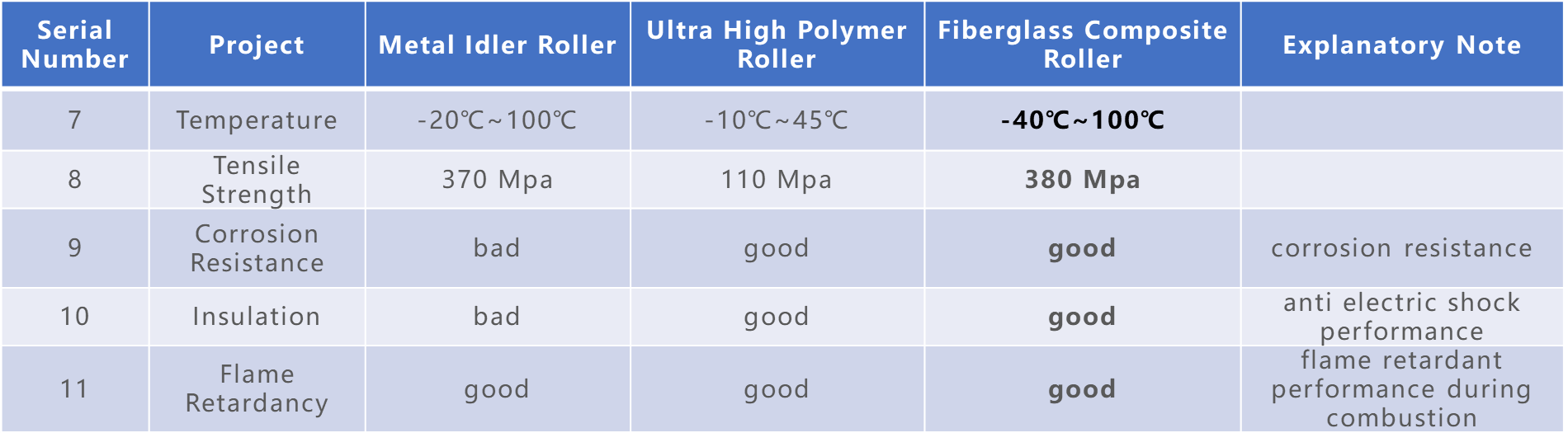

Roller is one of the core components of a belt conveyor. For the entire conveyor, its mass accounts for 30% -40% and its cost accounts for 25-30%. As a key component (consumable) in the daily management and maintenance of conveyors, the design of idlers plays an important role in the stable operation and normal maintenance of conveyors.

In recent years, the roller market in China has continued to grow, with a market size of tens of billions of yuan. Rollers are widely used in industries such as coal, metallurgy, electricity, ports, chemicals, grain, and building materials. Among them, the mining industry has the largest demand for rollers, accounting for more than half of the market share.

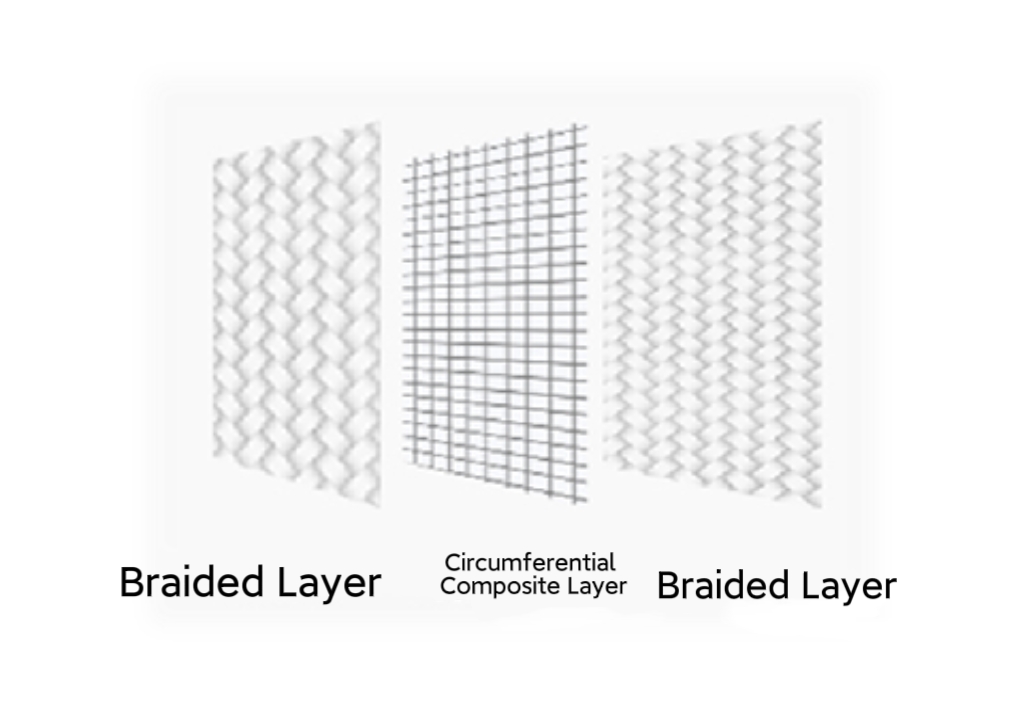

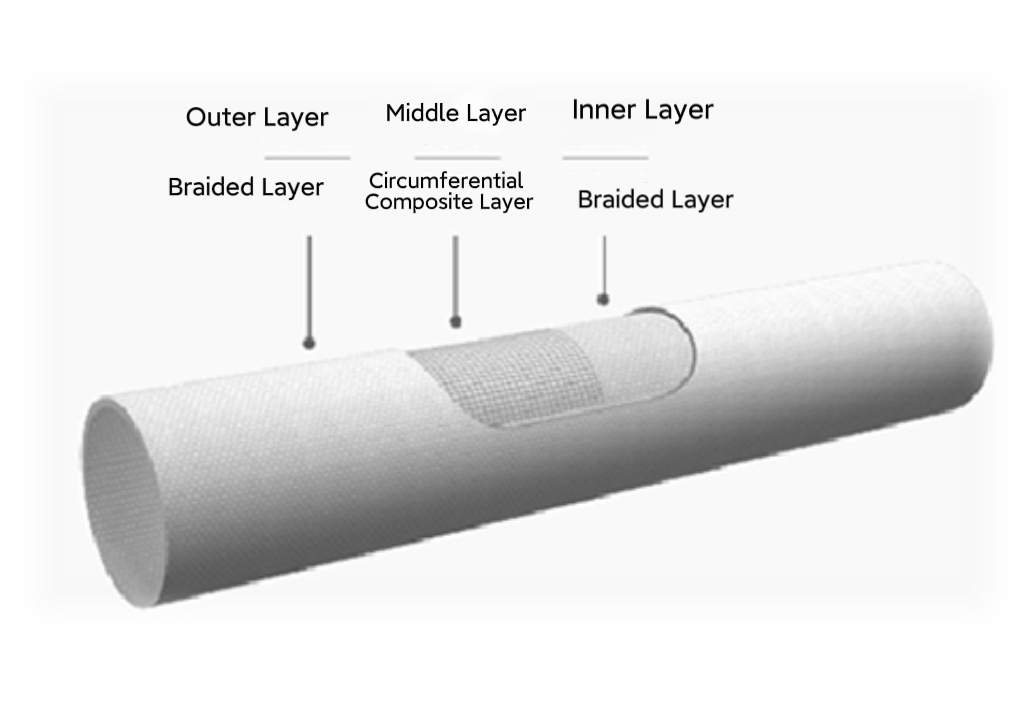

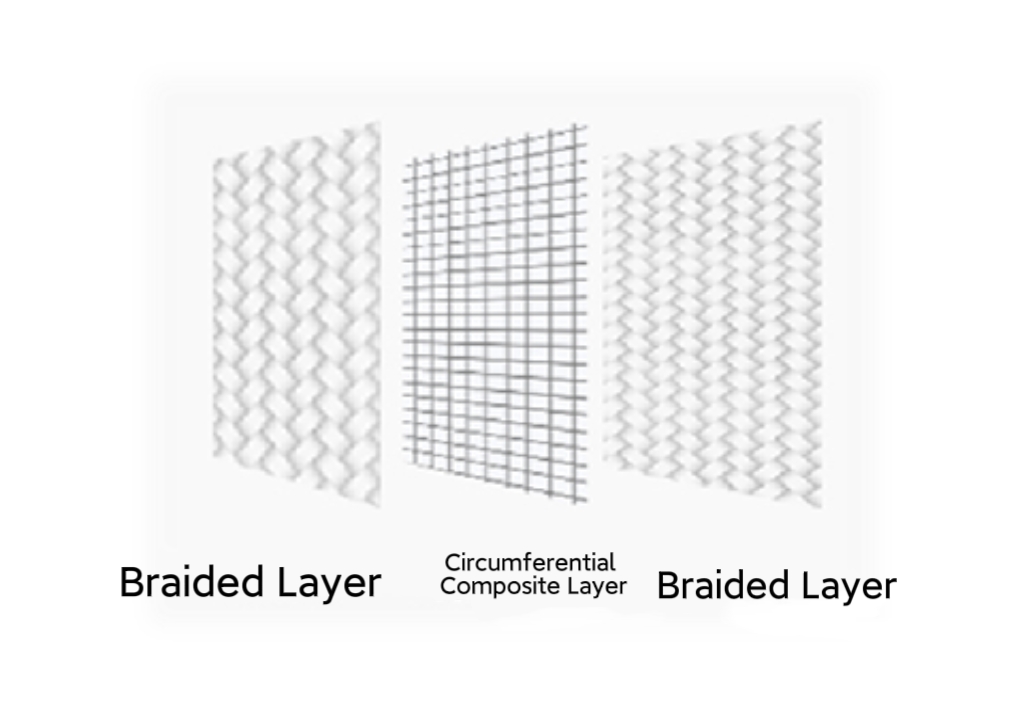

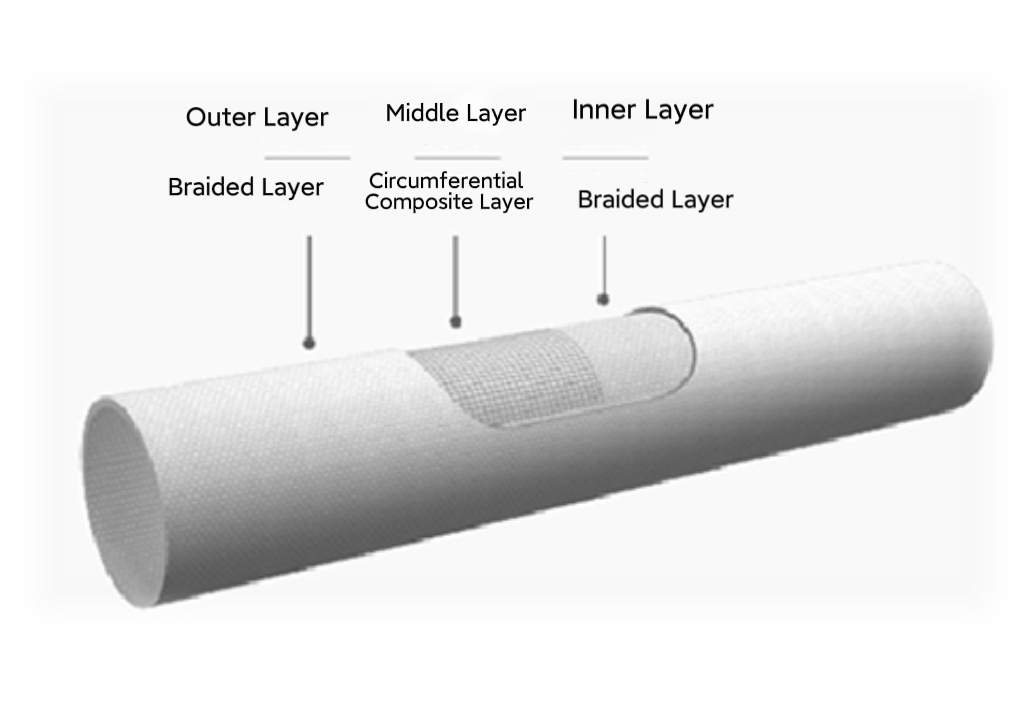

The fiberglass roller tube body is formed by online weaving and extrusion of the inner and outer wall weaving layers and the middle circumferential composite layer. The main raw materials are high-performance glass fiber, epoxy resin, graphite and other materials. Raw materials are widely used and have stable quality.

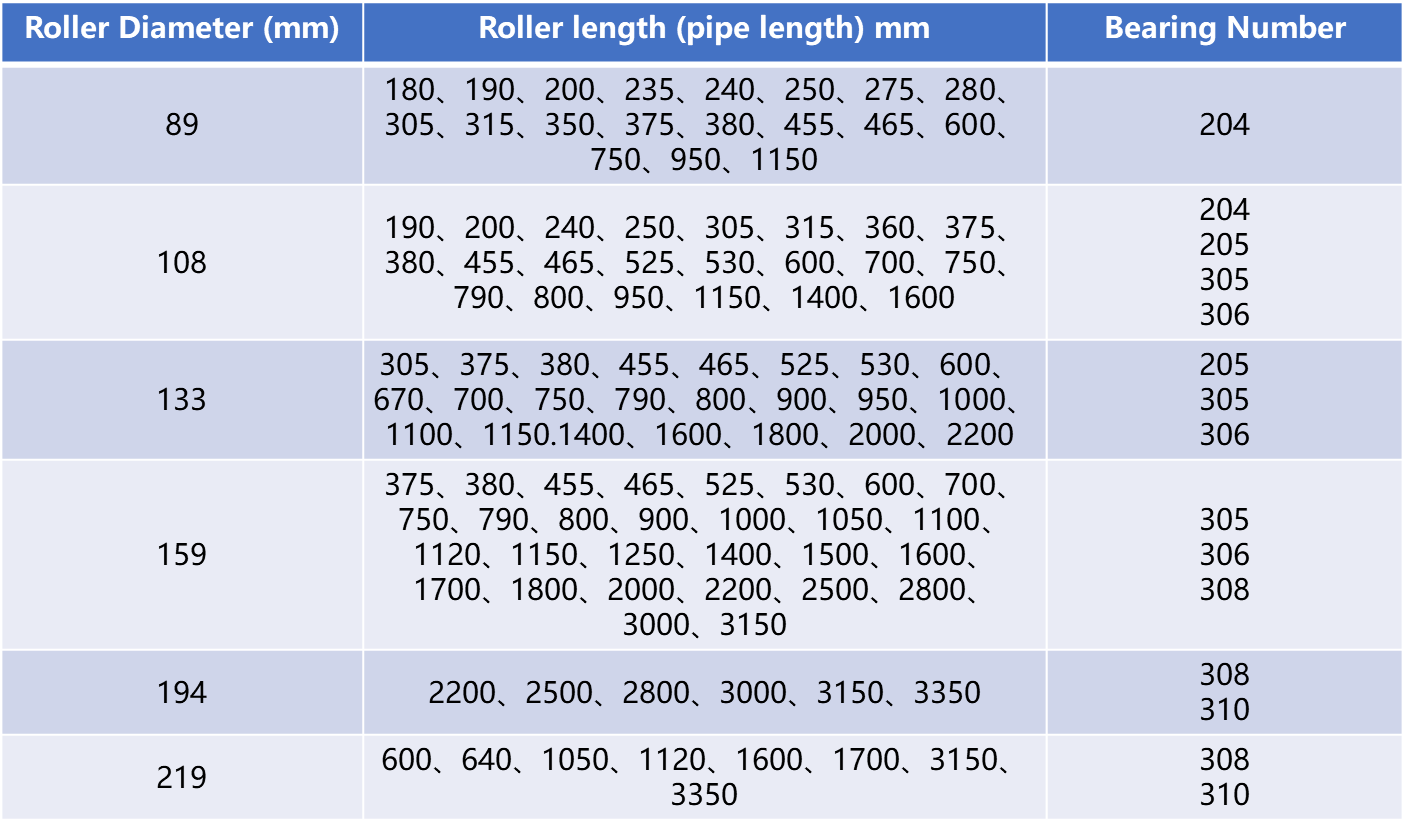

Both ends of the pipeline casing are equipped with bearing seats, bearings, sealing rings, shafts, retaining rings, and support plates.

Adopting a three-level sealing system (outer seal, labyrinth seal, grease seal).